The "three rates" of rational development and utilization of potassium salt resources refer to three indexes, such as the mining recovery rate (salt field recovery), mineral processing recovery rate and comprehensive utilization rate. It is the main index to evaluate the effect of exploitation and utilization of mineral resources by potassium salt enterprises. After research, it is determined that the low index requirements are as follows, and Huai 'an 14 dioxane manufacturer will introduce it to you!

First, the "three rates" index requirements

(a) mining recovery (salt pan recovery) rate

(1) the recovery rate of solid potassium salt mine (underground mining) is not less than 61%

② The recovery ratio of chloride brine in salt lake potassium salt mine is not less than 70%

③ The recovery ratio of salt lake potassium salt mine of sulfate brine is not less than 63%

(2) Mineral processing recovery rate

(1) solid potassium salt mine is not less than 63%

(2) The salt lake potassium salt ore of chloride brine is not less than 55%

(3) Salt lake potassium salt ore of sulfate brine is not less than 43%

(3) Comprehensive utilization rate

Mining enterprises must pay attention to the comprehensive utilization of associated resources. When newly built or expanded, the specific ways of comprehensive utilization of associated resources should be defined in the development and utilization plan, and the comprehensive utilization plan of associated resources should be scientifically planned.

(1) the utilization rate of tailings from solid potash ore dressing is not less than 30%.

② For salt lake potassium salt mine with chloride brine, the utilization rate of tailings is not less than 90%.

(3) For salt lake potash mine with sulfate brine, the utilization rate of tailings is not less than 75%.

Second, supervision and management

(a) the requirements of this index is an important basis for the supervision and management of potash enterprises by the competent department of land and resources to rationally develop and utilize mineral resources.

(two) the requirements of this index are the basis for compiling and reviewing the development and utilization scheme of potash resources and mine design. The "three rates" index of newly built or expanded potash mines should meet the requirements of this index.

(three) the existing production mines meet the requirements of this index within two years after the date of publication of this index. To meet the requirements of this index, the provincial competent department of land and resources shall organize and urge them to make rectification within a time limit, and the mining enterprises that have not yet reached the standard after rectification shall not pass the annual inspection on the development and utilization of mineral resources.

If the objective conditions, such as regional deposit characteristics, ore properties and technology, can not meet the requirements of this index, the mining enterprise shall explain the reasons, submit the demonstration report issued by the unit with corresponding design qualification, and put forward improvement measures. The supervision and management department at the same level of the original mining right registration authority demonstrates the report submitted by the mining enterprise and verifies its "three rates" index.

(4) The provincial competent department of land and resources may, according to the characteristics of potash resources within their respective administrative areas, formulate the index requirements not lower than this standard, and be responsible for supervising and managing the implementation of the index requirements of potash enterprises in their jurisdictions, conducting random checks and inspections from time to time, regularly announcing the list of potash enterprises that meet and do not meet the requirements of this index, and implementing social supervision and dynamic management.

Third, the index definition and calculation method

(a) mining recovery rate (salt pan recovery rate)

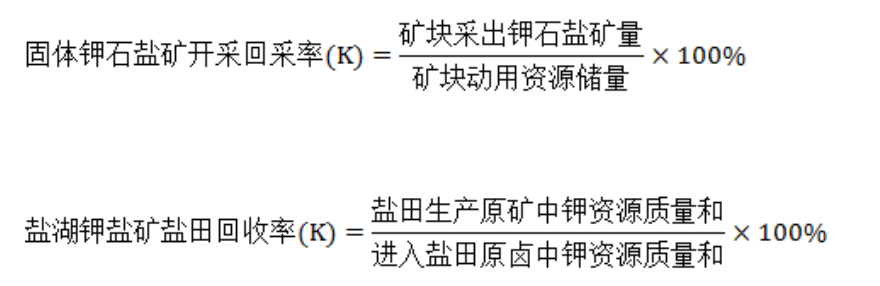

(1) mining recovery ratio (salt pan recovery ratio) definition.

Recovery rate of solid potassium salt mine: refers to the percentage of the actual amount of solid potassium salt mined from the block and the resource reserves used by the block. Among them, the resource reserves used in ore blocks refer to the sum of the mining amount and the mining loss of solid potassium salt ore in ore blocks.

Salt pan recovery ratio of salt lake potash mine: refers to the percentage of the total mass of potassium resources contained in raw ore (carnallite, potash salt and potassium mixed salt) produced by salt pan system and the mass of potassium resources in brine entering salt pan system.

② calculation method

Among them, the quality sum of potassium resources in raw ore produced in salt fields refers to the sum of the quality of potassium resources in raw ore crystallized out in metallogenic salt fields during the calculation period, which is obtained by subtracting the remaining amount in salt fields of the previous year from the sum of production statistics and the remaining amount in salt fields measured at the end of the year by mining enterprises.

The quality sum of potassium resources in brine entering salt field refers to the total quality of potassium resources in brine entering salt field system during the calculation period, which is obtained by mining enterprises through production measurement statistics.

In order to reduce the calculation error caused by potassium resources in brine in sodium salt pond, regulating pond and metallogenic pond, the recovery rate of salt field should be calculated in the normal production period of mine.

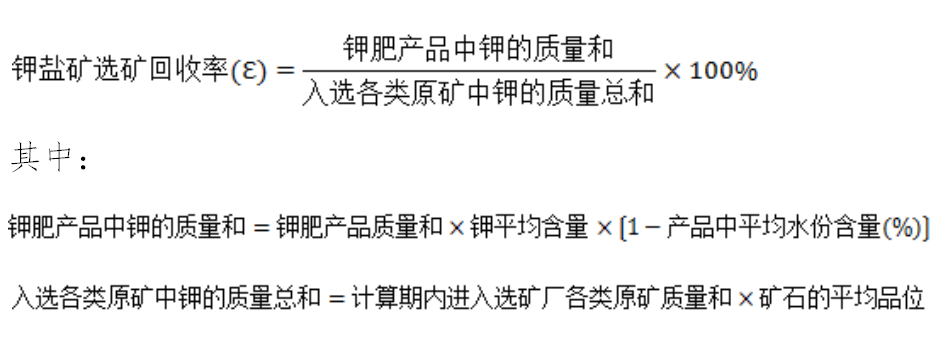

(2) Mineral processing recovery rate

① Definition

Beneficiation recovery rate of potash ore: refers to the percentage of the total mass of potassium in potash products and selected raw ores.

② calculation method

In which:

(3) Comprehensive utilization rate

① Definition

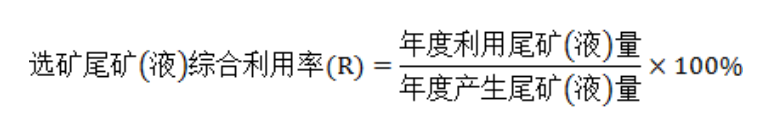

A comprehensive utilization rate of beneficiation tailings: it refers to the percentage of annual tailings utilization (including backfilling) and annual tailings produced during the beneficiation of potash ore.

B comprehensive utilization rate of beneficiation tailings: refers to the percentage of annual utilization of beneficiation tailings and annual tailings produced during beneficiation. Among them, the annual utilization amount of beneficiation tailings includes the amount of tailings returned by mining enterprises to salt fields for re-drying raw ore, and the amount of tailings entering the brine blending process unit.

② calculation method