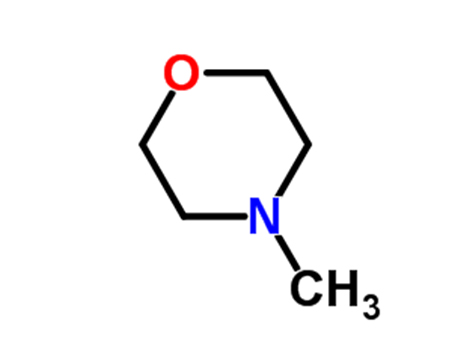

Properties, uses and production technology of N- methylmorpholine

[chemical properties]

Colorless transparent liquid with characteristic odor, soluble in organic solvent, miscible with water and ethanol.

[use]

① used as solvent, catalyst, emulsifier, organic synthesis intermediate, etc.

② It is used in organic synthesis and pharmaceutical industry, and also used as stationary liquid for gas chromatography

③ Methyl morpholine (NMM) is an intermediate of plant growth regulator.

(4) It is used for the production of extraction solvent, stabilizer, corrosion inhibitor, catalyst and drug of chlorohydrocarbon.

⑤ Pharmaceuticals and chemical synthetic media, organic synthetic raw materials, analytical reagents, extraction solvents, stabilizers of chlorinated hydrocarbons, corrosion inhibitors, catalysts, drug production, etc.

⑥NMM is soluble in water, alcohol and ether, and can be used as solvent and corrosion inhibitor for rayon, synthesis of rubber accelerator and other fine chemicals, polyurethane catalyst, and catalyst for synthesis of aminopenicillin and hydroxypenicillin. N- methylmorpholine oxide can be produced by double oxidation.

⑦ NMM is used as catalyst, extractant, stabilizer of chlorohydrocarbon, corrosion inhibitor, analytical reagent and pharmaceutical manufacturing.

⑧ Extraction solvents, catalysts, corrosion inhibitors, analytical reagents and pharmaceutical manufacturing, etc.

[production method]

(1) it is obtained by reaction of morpholine with formaldehyde and formic acid. Formaldehyde was slowly added to morpholine, while stirring, formic acid was added dropwise, and the reaction automatically refluxed and carbon dioxide was released. Heating and refluxing for 4-5h after adding formic acid, cooling, adding sodium hydroxide, distilling immediately, collecting all fractions below 99℃, adding sodium hydroxide to saturation, cooling to separate oil layer, drying, fractionating, and collecting fractions at 114.5-117℃ to obtain the finished product.

② Another method uses dichloroethyl ether, monomethylamine aqueous solution, liquid alkali and other raw materials for one-step synthesis, which has short process, simple equipment, mild process conditions, less dosage, high product yield and good quality.

(3) The preparation method is to slowly drop formaldehyde into morpholine, drop formic acid while stirring to react, automatically reflux and release carbon dioxide. After formic acid is added, it is heated and refluxed for 4-5h, cooled, and then added with sodium hydroxide for immediate distillation. All fractions with boiling point before 99℃ are collected, and then sodium hydroxide is added into the fractions to be saturated, cooled to separate oil layer, dried and fractionated to obtain the product.

[category]

flammable liquid

[toxicity classification]

Poisoning

[acute toxicity]

Oral-rat LD50:1960/kg;

Oral-mouse LD50:1970 mg/kg

[stimulus data]

Eyes-rabbit 920 micrograms;

Skin-Rabbit 460 mg Mild

[Flammability hazard characteristics]

Flammable in case of open flame, high temperature and oxidant;

Combustion produces toxic nitrogen oxide smoke

[storage and transportation characteristics]

The warehouse is ventilated and dried at low temperature;

Store separately from oxidants and acids

[fire extinguishing agent]

Dry powder, dry sand, carbon dioxide, foam, 1211 fire extinguishing agent

[professional standards]

TWA20 20mg/m3; STEL40 mg/m3