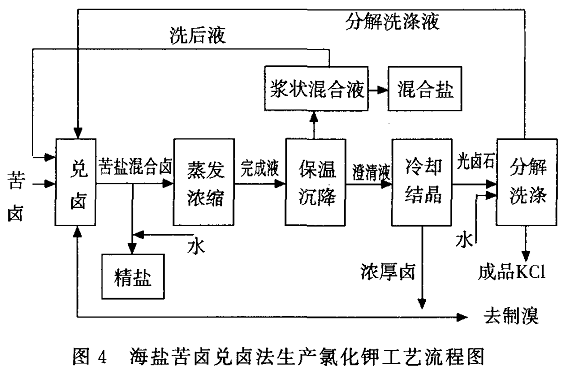

According to the chemical raw material manufacturers, this process is mainly based on the different laws of solubility of main salts such as magnesium chloride, sodium chloride, magnesium sulfate, potassium chloride, etc. which change with temperature. Under the condition of heating and evaporation, sodium chloride and magnesium sulfate (in the form of MgSO4 H2O) are precipitated first, and after solid-liquid separation, the mother liquor temperature is lowered. Potassium chloride and magnesium chloride are precipitated from the mother liquor in the form of double salt carnallite, and carnallite is obtained after solid-liquid separation, and water is added to dissolve it. The process flow is as follows.

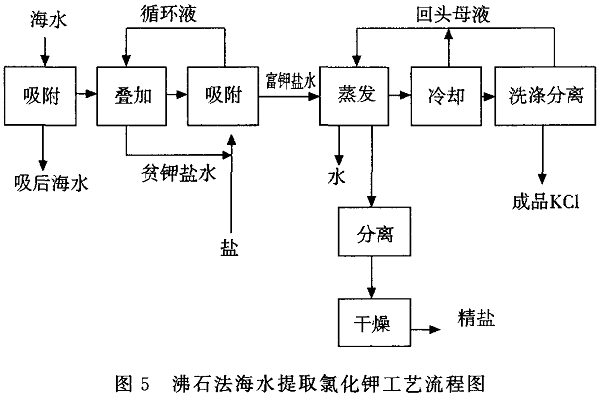

First, the process of extracting potassium chloride from seawater by zeolite method

According to the process, natural clinoptilolite is used as an ion exchanger and sodium chloride is used as an eluent, and potassium in seawater is enriched by ion exchange between K in seawater and Na on zeolite, so as to prepare potassium salt-rich water. Potassium chloride is prepared from potassium salt-rich water by evaporation, salt precipitation, cooling and crystallization, washing, separation and drying, and refined salt is co-produced. The process flow is as follows.

Although it is feasible to extract potassium chloride from seawater, there are some problems such as high salt consumption, high energy consumption and high cost, so it is difficult to carry out large-scale industrial production.

Although there are many methods to produce potassium chloride in the industry at present, each method has its own advantages and disadvantages. In the process of selecting potassium chloride production technology, we must consider the specific situation of potassium mine resources in the project location, consider various factors affecting potassium chloride production, and choose the method with low production cost, high potassium yield and good product quality to produce, so as to improve the utilization of resources and reduce the waste of resources.

From the above process analysis, we can see that the methods of extracting potassium chloride are different according to different raw materials. Even if the raw materials are the same, the finished product grade, raw ore consumption, total resource recovery rate, product cost and other aspects of potassium chloride obtained are also different. At the same time, each method has its advantages and disadvantages.