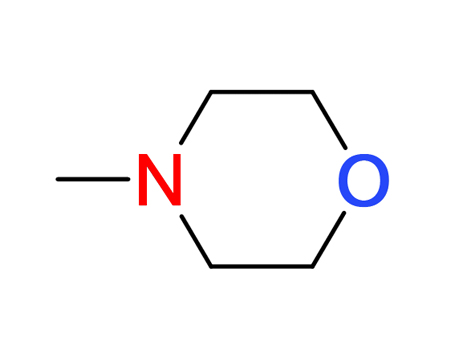

Today, the professional chemical raw materials factory introduces the operation of N- methylmorpholine recovery, dehydration, distillation and safety precautions!

-,operation

(1) check whether the valves, pipes and cooling water at the bottom of the distillation pot are normal.

(2) After pumping morpholine to be recovered and benzene solution into the kettle, the temperature is raised to the full reflux state, and dehydration is carried out (the kettle temperature is about 110℃ and the top temperature is about 80℃)

(3) After the water is removed (no water drops appear in the glass tube), open a few receiving valves to control the flow rate below 0.25m3/n, and then lower the receiving amount when the top temperature rises to 100℃, then sample and detect at 114℃, close the receiving valve, reflux for 1 hour, and receive morpholine when the top temperature rises to 115℃.

(4) When receiving morpholine, fully open the receiving valve until the kettle is basically steamed, stop the distillation, take samples for inspection, and hand them over to condensation for reuse after passing the test.

Second, the safety precautions

(1) Benzene is a toxic, flammable and explosive liquid, and it is strictly forbidden to run, drip and open fire.

(2) Contact inhalation of personnel shall be treated in time according to MSDS requirements.

(3) It is strictly prohibited to pump and discharge benzene with ungrounded conductive plastic pipe and steel wire pipe.

(4) During dehydration, observe the stratification of water separator at any time, and do not separate benzene.

(5) The recovered morpholine can be used only after the moisture is qualified.

(6) When recovering benzene, the reflux ratio and top temperature must be controlled to sample and analyze the morpholine content of 99%